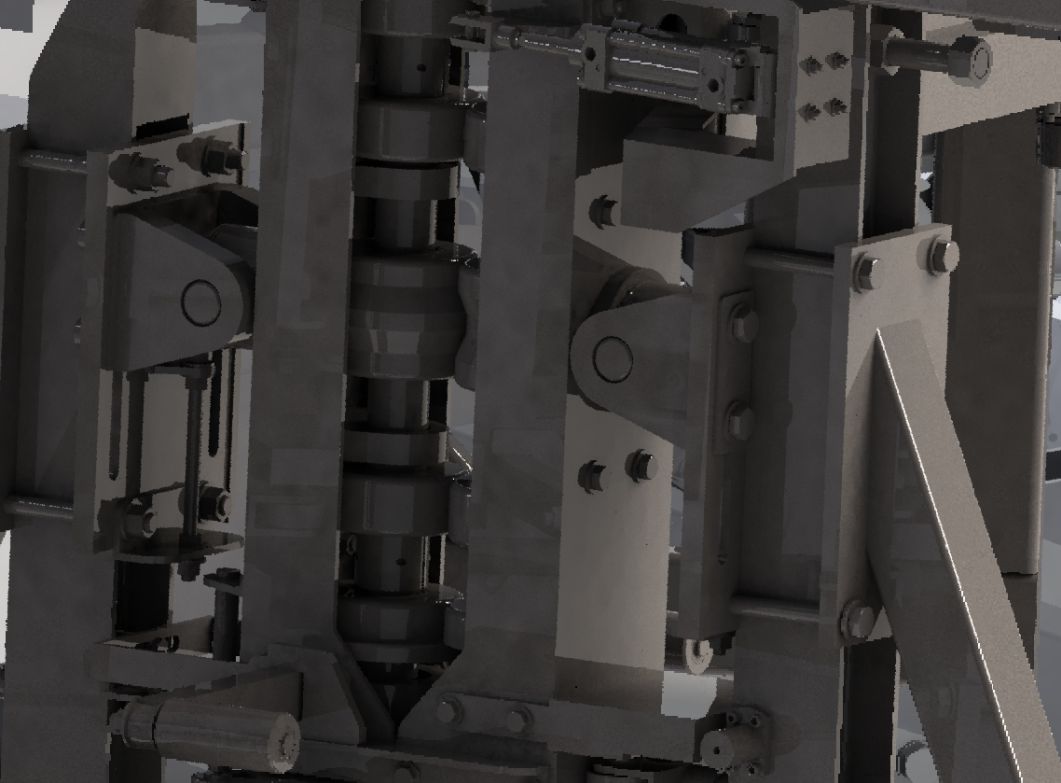

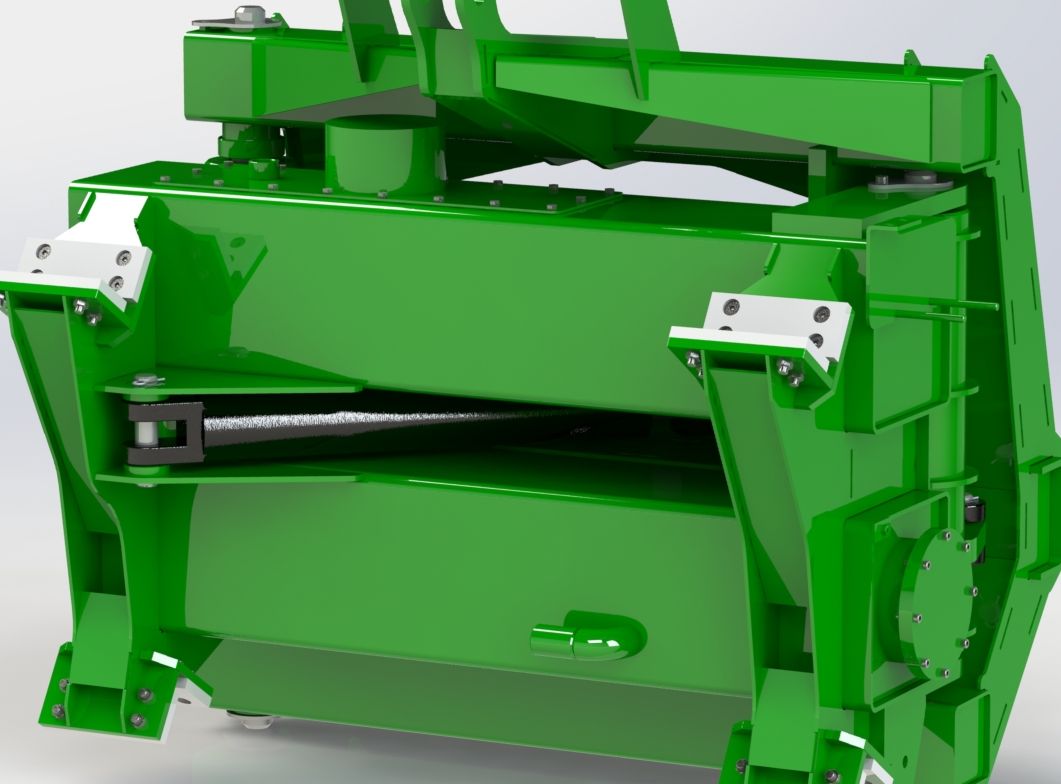

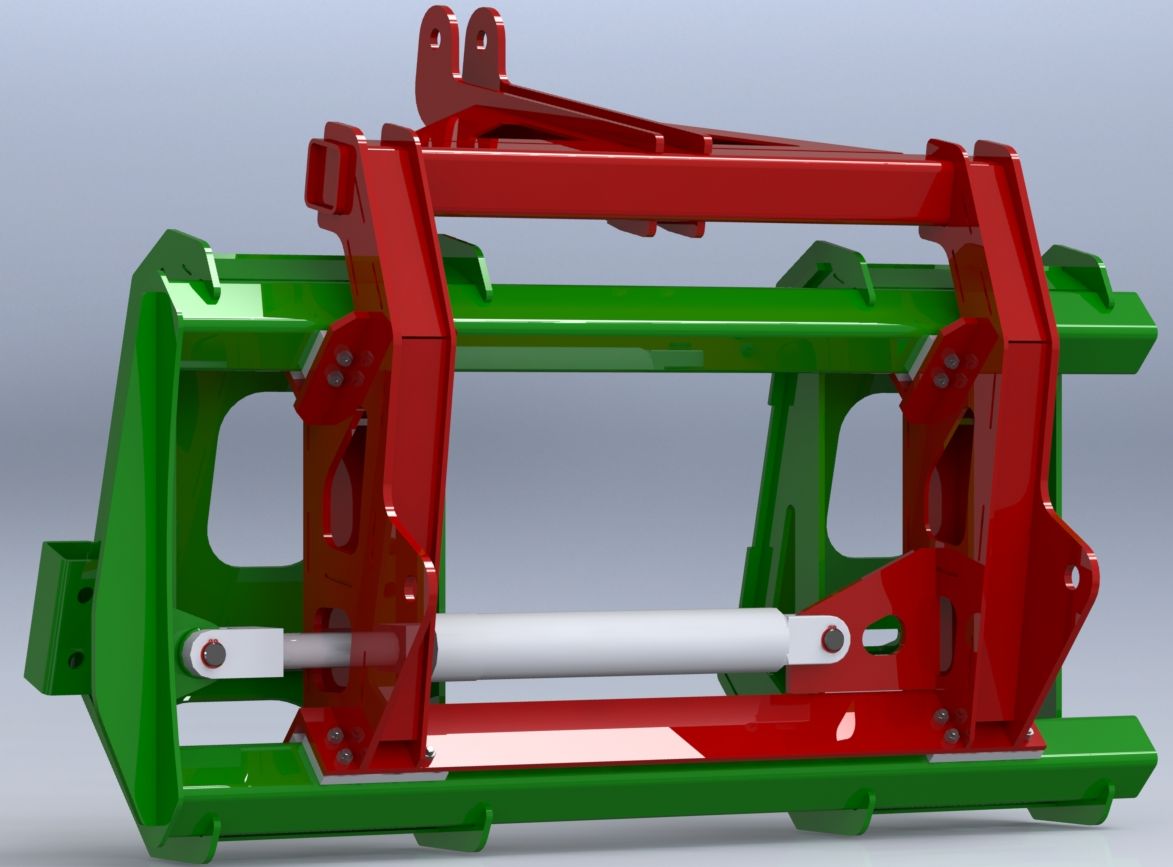

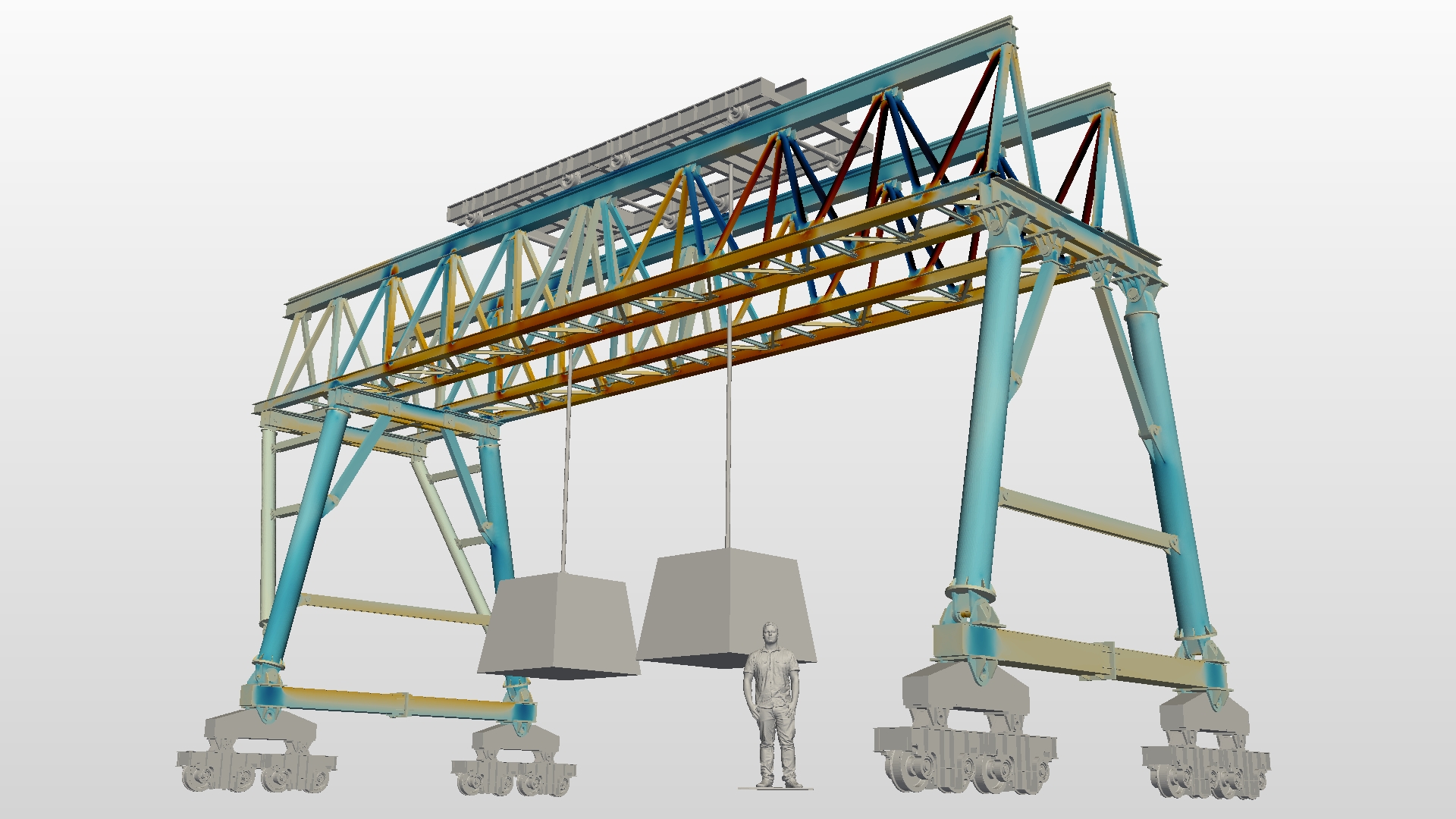

MACHINE DESIGN

Machine design is a creative process that requires a clear understanding of the overall objectives and a good attention to detail. The designer must draw on a mix of theoretical knowledge, practical experience and intuition. I believe that quality must be built into each and every stage of the design.

I use SoildWorks for 3D CAD modelling. My skills include:

Part and assembly modelling

Mechanisms

Configurations

Surfacing

Sheet metal

Rendering

Direct editing

Weldments

Drawings for manufacture (profile cutting, CNC machining, 3D printing etc)

Bill of materials

Certification to Australian Standards

ANALYSIS

Custom Machines is a SimScale consulting partner . SimScale is a powerful cloud based simulation tool. You can find my SimScale public projects here.

ParaView is used for post processing of simulation results.

I work predominately with structural applications using Finite Element Analysis. I work with the following analysis types:

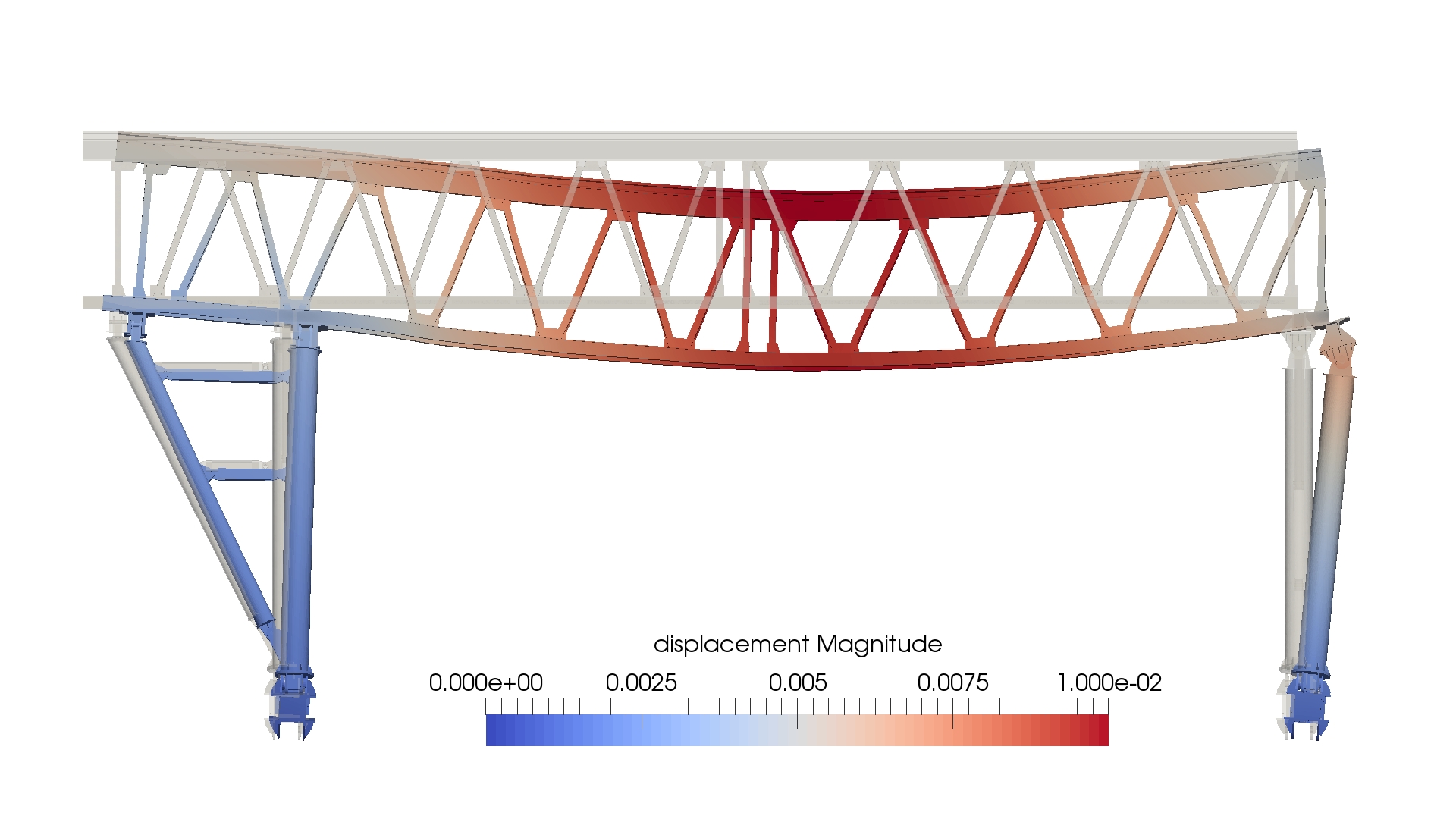

Solid Mechanics (linear and non-linear)

Static

Dynamic

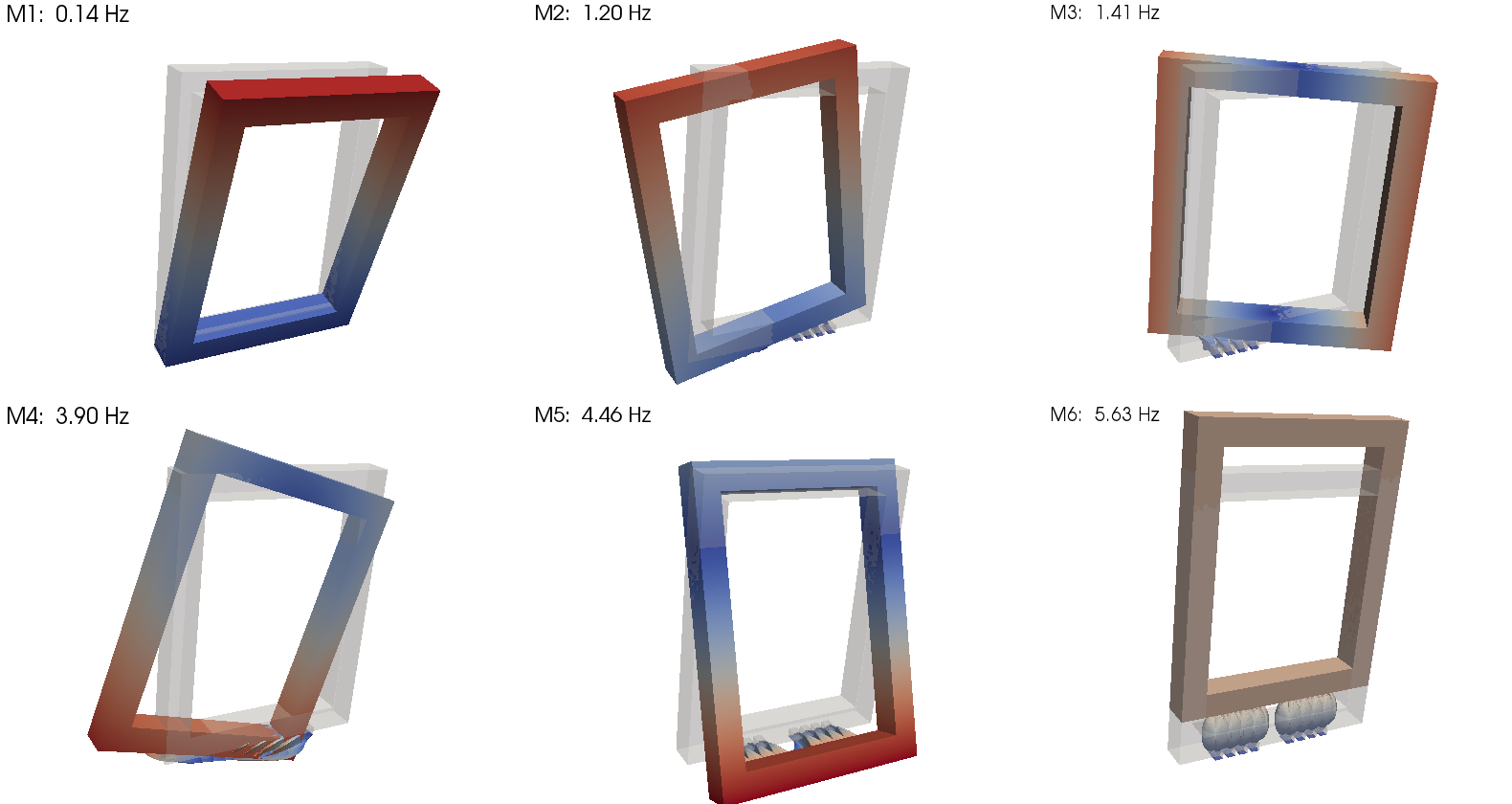

Frequency

Modal

Harmonic

Buckling

Thermal (linear and non-linear)

Steady state and transient

Automation

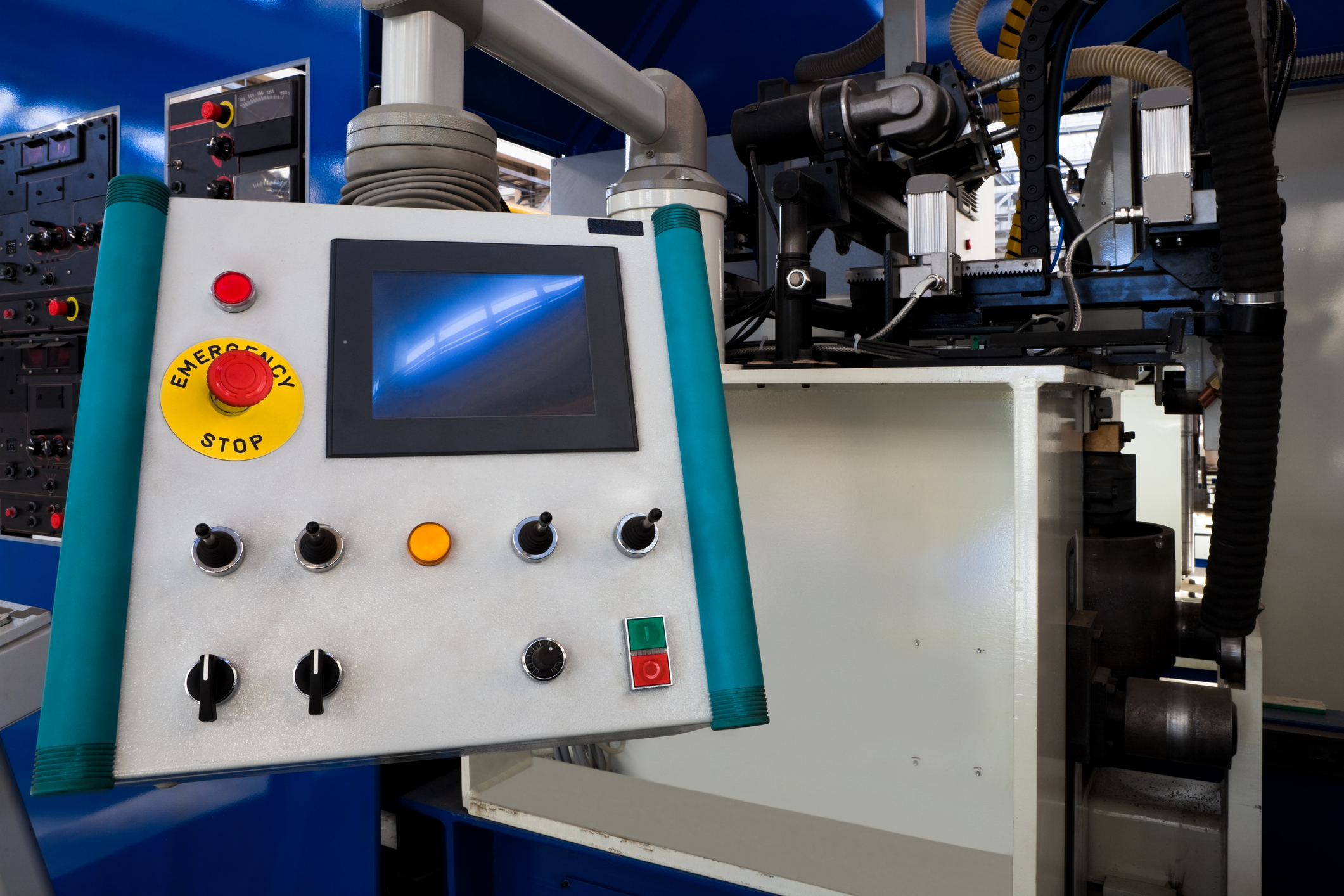

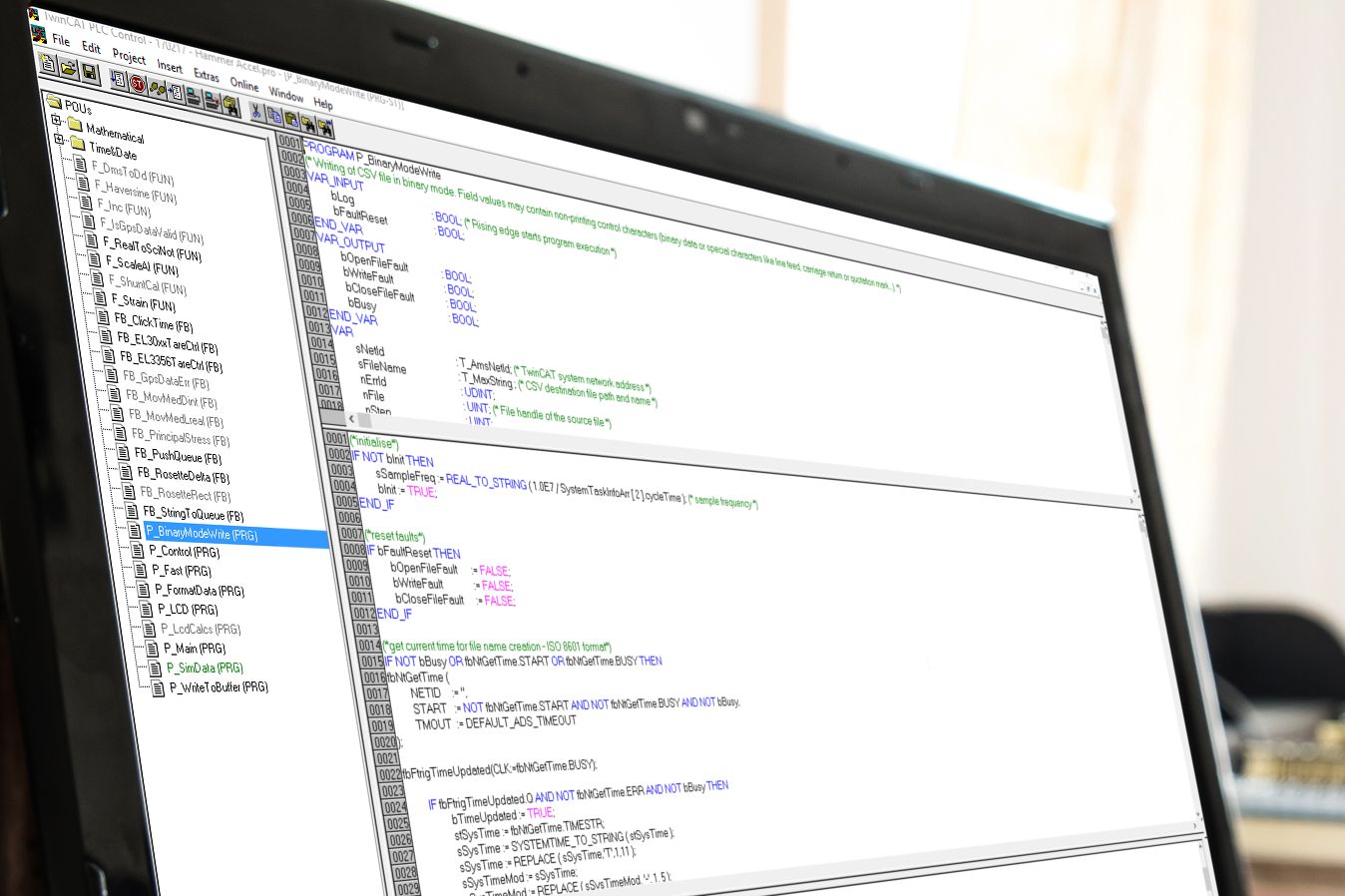

I create user interfaces that are simple and intuitive. I produce code that is well structured and modular. Using these principles I produce systems that are characteristically robust and reliable. They are easy to troubleshoot, maintain and extend. In short, they are a pleasure to use.

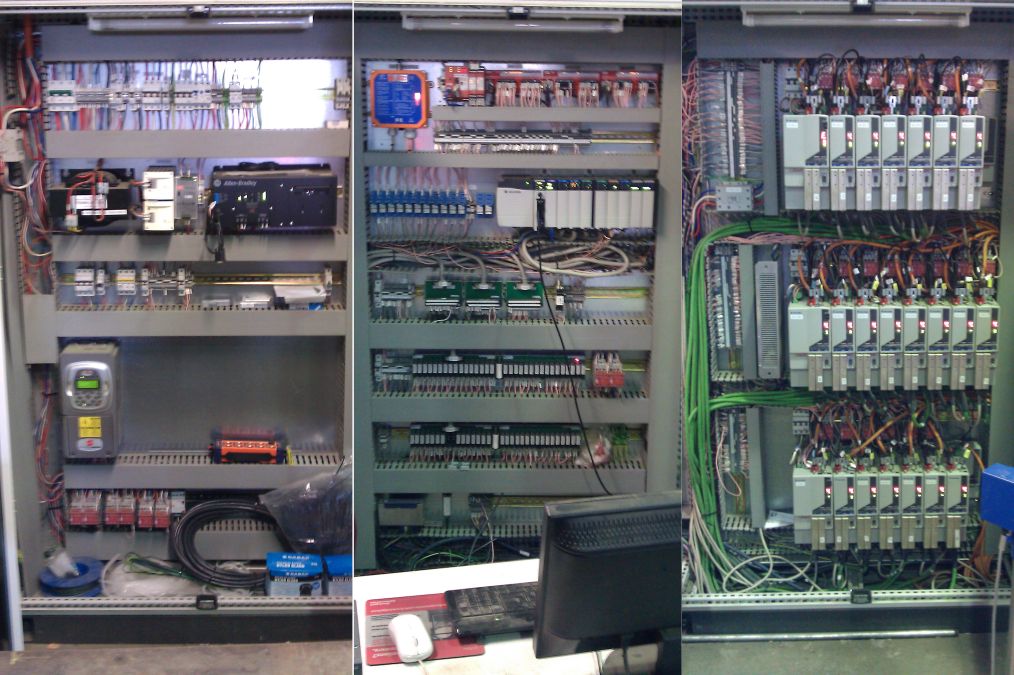

I have experience with a wide range of automation controllers including Beckhoff, Allen-Bradley and Koyo. I have expertise in the following areas:

PLC programming (especially with ICE 61131-3 programming languages)

Motion control (servo applications)

HMI design

If you would like to see your industrial machine come to life, please give me a call today.

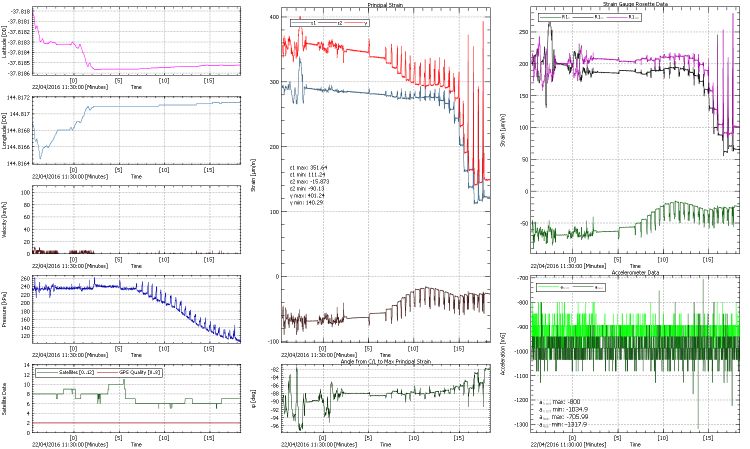

TEST & MEASUREMENT

Data acquisition is a powerful tool for troubleshooting machine failure. It can also be used for life prediction, validation of simulation results and process optimisation.

I have experience in measuring the following quantities:

strain (strain gauges)

force (load cells)

displacement (laser distance sensors and inductive proximity sensors)

acceleration (piezoelectric and MEMS)

temperature (thermocouples, RTDs and thermal imaging)

pressure (transducers)

location (GPS)

I have extensive experience is in the area of stress analysis and strain gauging.

I use HBM the Beckhoff hardware for data acquisition. Kst is used for live plots and post processing.